SAP MFS: Efficient Integration of Automated Warehouse Technology with SAP EWM

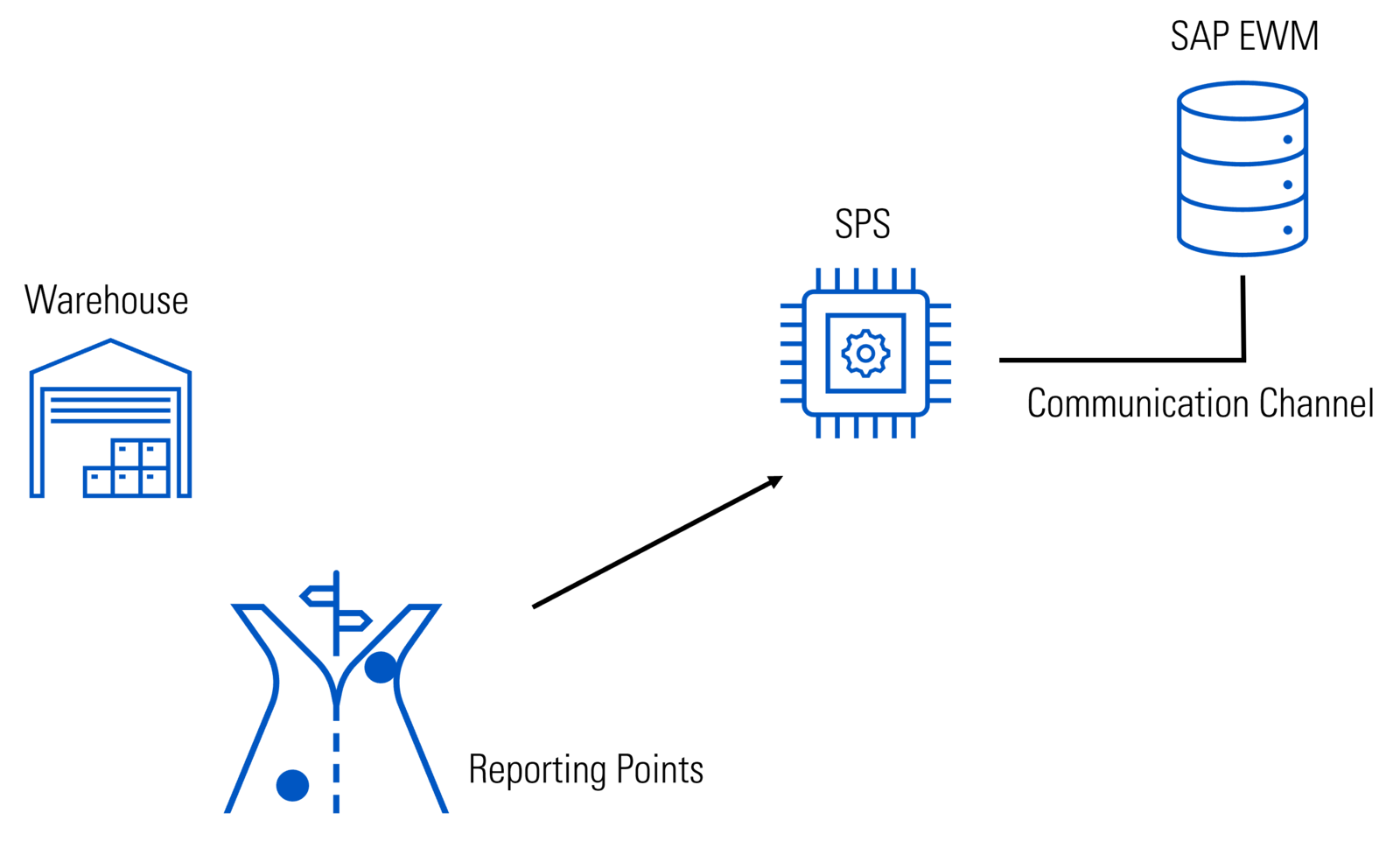

Companies today are looking to implement lean, harmonized processes to improve the resilience of their supply chains. The SAP Material Flow System, or SAP MFS for short, is a component in SAP Extended Warehouse Management (EWM) that is designed to efficiently control material flow in automated warehouses. SAP MFS enables the seamless integration of programmable logic controllers (PLCs) and other automation components with SAP EWM. The integration of automated warehouse and materials handling technology into logistics processes opens up numerous possibilities for optimizing material flows and managing stock, enabling companies to shorten lead times and increase process flexibility while at the same time reducing operating costs.

With SAP MFS, companies can optimally manage their partially or fully automated warehouses by ensuring a smooth flow of materials. The system ensures that the various warehouse processes managed by automated systems are seamlessly integrated with the warehouse management features of SAP EWM, enabling companies to maximize warehouse efficiency, maintain an overview of their stocks, and keep tight control over their warehouse processes. It is ideal for companies with complex warehouse structures and automated warehouse management systems.

What are the Main Features of EWM for Automated Warehouse Management?

The integration of a material flow system in SAP Extended Warehouse Management (EWM) enables the efficient management of fully automated warehouse systems. The integration of EWM and MFS is seamless and direct, without requiring external interfaces or a separate warehouse management computer.

Connecting materials handling technology to the EWM system and mapping this information enables various SAP EWM MFS features to be used. These features comprehensively support goods receipt, goods issue, picking and consolidation/deconsolidation processes and enable integrated processing of the resulting warehouse tasks.

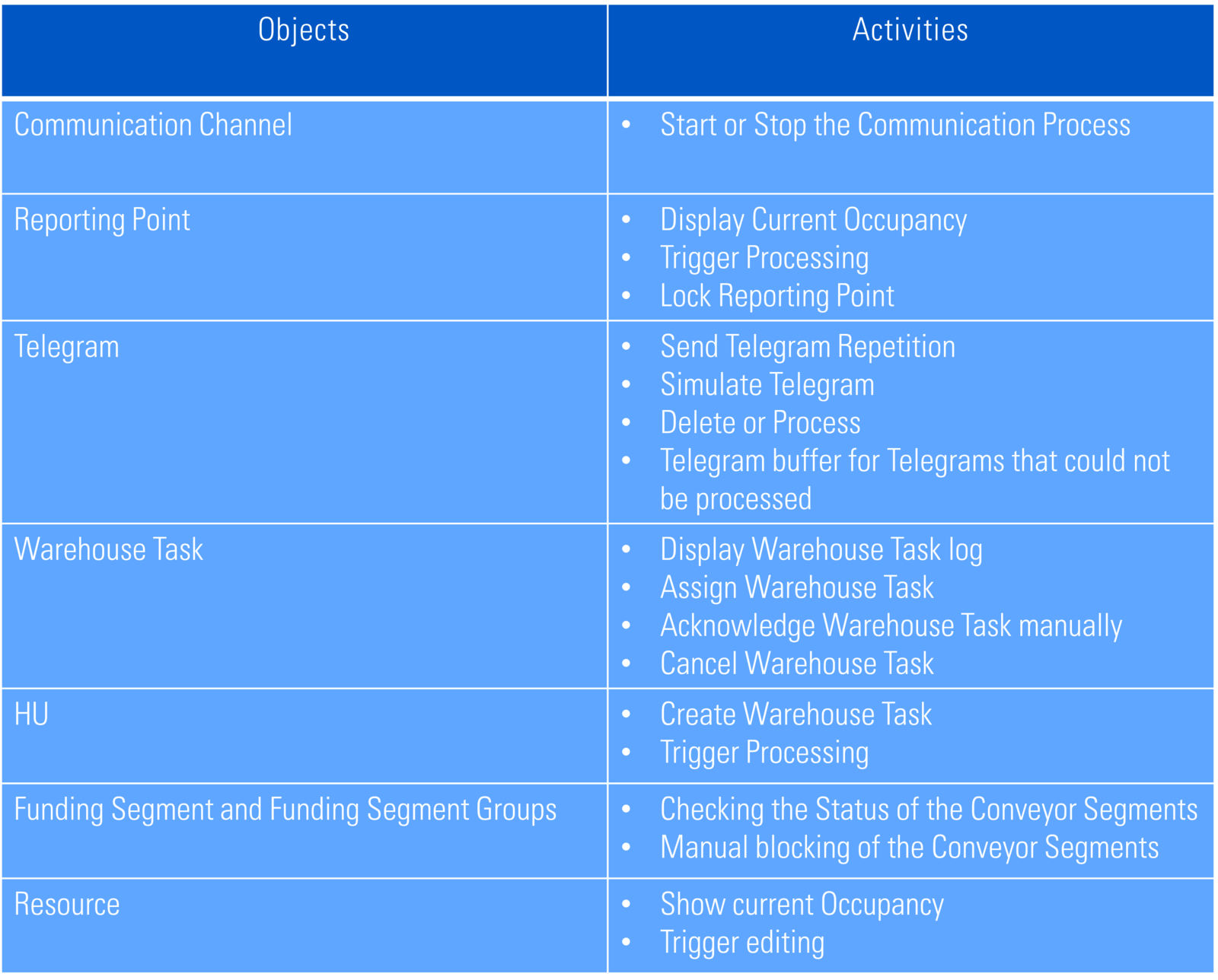

The warehouse management monitor in SAP EWM enables transparent monitoring, reporting, and further processing of status and data from the material flow system.

From the warehouse monitor, you can perform the following activities: